Categories of Auxiliary Equipment

1. Wire Straightening Machines

Wire straightening machines are essential for preparing the wire before it enters the hexagonal wire mesh machine. These machines ensure that the wire is perfectly straightened, which is critical for producing uniform and high-quality mesh.

Features:

- Adjustable straightening rollers

- High-speed operation

- Precision control for different wire diameters

Uses:

- Preparing wire for hexagonal mesh production

- Improving mesh quality by reducing wire deformation

2. Wire Feeding Machines

Wire feeding machines automate the process of feeding wire into the hexagonal wire mesh machine. This ensures a consistent and controlled supply of wire, reducing manual labor and increasing production speed.

Features:

- Automatic wire feed control

- Adjustable feed rate

- Compatibility with various wire diameters

Uses:

Enhancing production efficiency

Reducing manual handling and associated errors

3. Mesh Cutting Machines

Mesh cutting machines are used to cut the finished hexagonal wire mesh into desired lengths and shapes. These machines offer precision cutting, ensuring clean edges and reducing waste.

Features:

- High-precision cutting blades

- Adjustable cutting lengths

- Automated cutting process

Uses:

- Customizing mesh lengths for different applications

- Reducing material waste and enhancing productivity

4. Coiling and Packing Machines

Coiling and packing machines automate the process of coiling the finished wire mesh and preparing it for storage or shipment. These machines help in maintaining the integrity of the mesh and make handling easier.

Features:

- Automatic coiling mechanism

- Adjustable coil sizes

- Integration with packing systems

Uses:

- Streamlining the packing process

- Ensuring secure and compact coils for easy transport

Different Features and Uses

Automated Control Systems

Many auxiliary machines come equipped with automated control systems that enhance precision and ease of operation. These systems often feature programmable settings and digital interfaces for real-time monitoring and adjustments.

Features:

- Digital control panels

Programmable settings for different wire specifications

Real-time monitoring and feedback

Uses:

- Increasing operational efficiency

- Reducing human error and enhancing product consistency

Customizable Settings

Auxiliary equipment often includes customizable settings to accommodate various production requirements. This flexibility allows manufacturers to produce a wide range of mesh sizes and wire diameters.

Features:

- Adjustable rollers and blades

- Variable speed controls

Uses:

- Producing diverse mesh products

- Adapting to specific project needs

Different Parameters of Auxiliary Equipment

- Wire Straightening Machines

Wire Diameter Range: 0.5 mm to 2.5 mm

Speed: Up to 100 meters per minute

Power Consumption: 1.5 kW - Wire Feeding Machines

Wire Diameter Range: 0.7 mm to 3.0 mm

Feed Rate: Adjustable from 10 to 50 meters per minute

Power Consumption: 2.0 kW - Mesh Cutting Machines

Cutting Width: Up to 4 meters

Cutting Thickness: Up to 5 mm

Power Consumption: 3.0 kW - Coiling and Packing Machines

Coil Diameter: Adjustable from 0.5 meters to 2 meters

Packing Speed: Up to 20 coils per hour

Power Consumption: 2.5 kW

Main parameter :

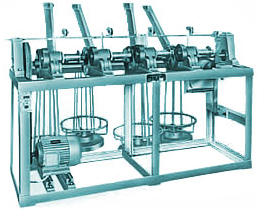

Coiling Machine serves to make wires into form of coils to be used as weft wires, on the Wire Netting Machine for purpose of producing hexagonal screens.

NO. of coiling spindles: 4

Dia. of coiling shaft: 10,12,16 mm

Suitable for wire diameters: 0.38-0.90 mm

Total Weight: 350 kg

Power Required: 1.5 KW

Main parameter :

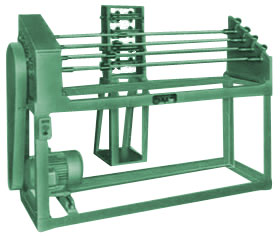

Coiling Machine serves to make wires into form of coils to be used as weft wires, on the Wire Netting Machine for purpose of producing hexagonal screens.

NO. of coiling spindles: 4

Dia. of coiling shaft: 10,12,16 mm

Suitable for wire diameters: 0.38-0.90 mm

Total Weight: 350 kg

Power Required: 1.5 KW