Machine Specifications:

Mesh Sizes

The machine can produce a wide range of mesh sizes based on specific customer requirements. Standard mesh sizes include:

- 1/2" (12.7 mm)

- 5/8" (15.9 mm)

- 3/4" (19 mm)

- 1" (25.4 mm)

- 1-1/4" (31.75 mm)

- 1-1/2" (38.1 mm)

- 2" (50.8 mm)

- 3" (76.2 mm)

- 80 x 100 mm

Weaving Widths

- Single weaving width: Up to 2.5 m

- Double weaving width: Up to 1.25 m each

Production Speed

- Maximum speed of 65 meshes per minute, adjustable depending on the raw material type.

Alarm System

- Automated alarm triggers when wire breaks, mesh breaks, or preset mesh length is achieved.

Reverse Twisted Hexagonal Mesh Machine |

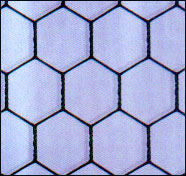

Hexagonal Wire Netting |

Functional Features

- Smooth Operation and Noise Reduction: The machine is designed for minimal noise and consistent operation with an alarm system to notify operators of breaks or when the preset length is reached.

- Clutch Brake Device: Incorporates a clutch brake system for spot movement. This design ensures flexible operation with no high skill requirement for the operator.

- Uniform Mesh Openings: The machine maintains even and flat mesh openings and allows for wire additions at any point during the weaving process.

- Lubrication and Maintenance: Offers reliable lubrication and easy maintenance for prolonged machine life.

- Durable and Strong: Built with strong materials to handle high-volume production while ensuring consistent quality.

Customization and Additional Components:

- Thread Spool Machines: Complementary machines designed for efficient winding and spooling of the thread.

- Weaving Machine Fittings: A range of specialized fittings for maintaining and enhancing weaving machine performance.

- Custom Machine Design: The machine design can be tailored to meet particular customer requirements, ensuring timely delivery and quality assurance.